All QM-relevant processes and parameters are globally standardised and subject to constant quality monitoring for compliance with SCHÜTZ SHEQ policy.

Superior product performance thanks to

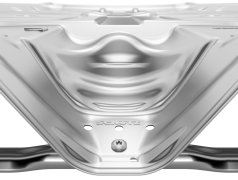

quality and original components.

As a composite packaging, the IBC owes its quality and performance to the perfect interplay of its individual components. As there are practically no IBC components that do not affect the safety of the container, SCHÜTZ develops and tests all components for possible interactions throughout the full packaging life cycle. That is why customers using reconditioned SCHÜTZ ECOBULKS should make sure that only OEM parts were used in the reconditioning process.