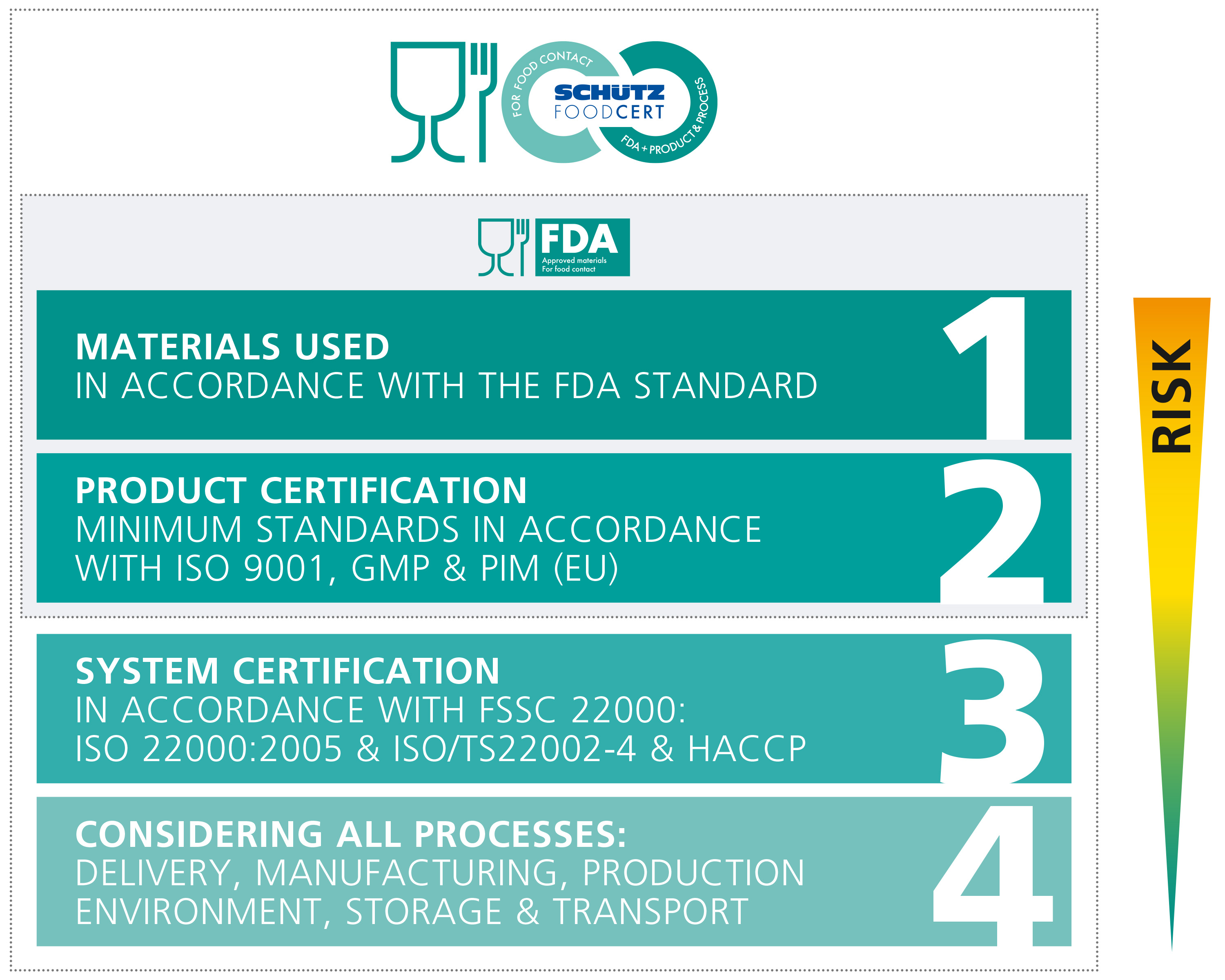

Traditionally, the focus for FDA-approved plastic packaging is on the type and the characteristics of the materials, in order to assess their suitability for contact with food, pharmaceutical products and cosmetics. Until now, potential risks within the manufacturing process have been largely disregarded in the FDA standard. This can lead to serious contamination.

In order to prevent process-related sources of contamination effectively, SCHÜTZ has additionally implemented a dedicated management system in compliance with DIN EN ISO 22000:2005. Following meticulous HACCP risk analysis, SCHÜTZ has introduced prevention programmes in accordance with ISO/TS 22002-4 that cover the entire chain – from the delivery of raw materials to the dispatch of finished products.

This comprehensive approach means that SCHÜTZ FOODCERT offers the highest possible degree of quality and safety for your filling products. Our FOODCERT standard is based on the Food Safety System Certification (FSSC) 22000, which is recognised by the Global Food Safety Initiative (GFSI), thus documenting the highest standard of food safety for your customers.